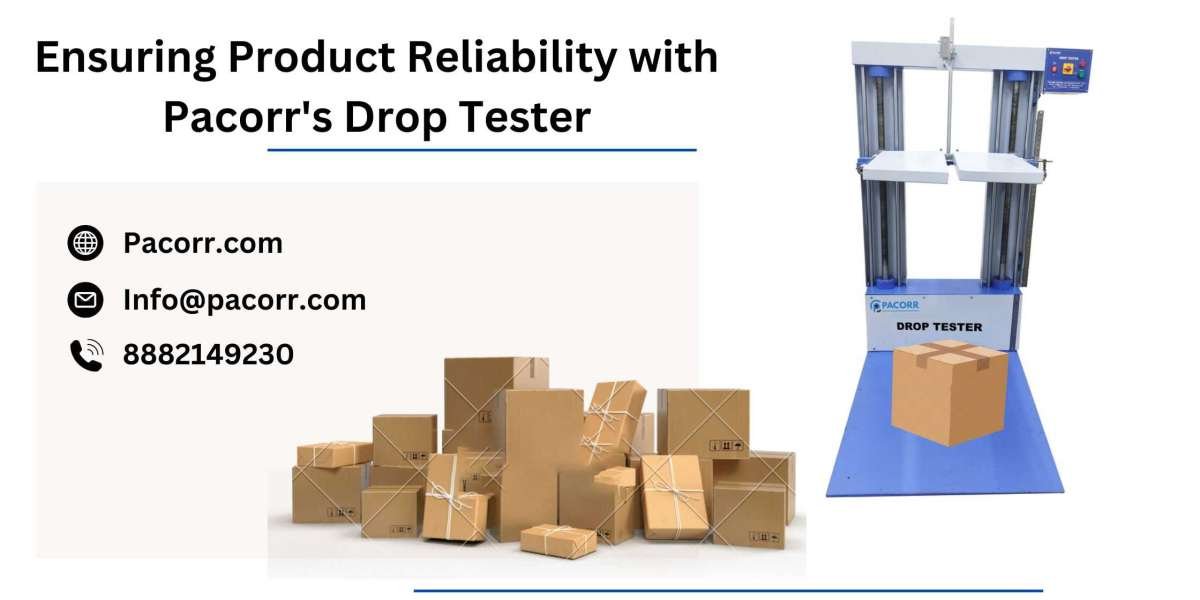

Drop Tester helps manufacturers simulate the impact and drops that products might encounter during shipping, ensuring that their packaging is both robust and reliable.

What is a Drop Tester?

A Drop Tester is a piece of equipment designed to assess the durability of packaging materials by simulating the impact a product would experience if dropped during shipping. This test helps identify whether the packaging is strong enough to protect its contents, and it provides businesses with the ability to fine-tune their designs before production begins.

How Does It Work?

The Drop Tester functions by lifting a packaged product to a specific height and allowing it to fall onto a hard surface. The machine can be adjusted to simulate different conditions, such as varying drop heights and surface types, to mimic real-life shipping scenarios. After the drop, the packaging is carefully inspected for any signs of damage to the product or the packaging itself. This allows manufacturers to detect weak points in their packaging and improve its design for better protection.

Why Drop Testing Is Crucial for Your Business

1. Improved Packaging Strength

One of the biggest advantages of using a Drop Tester is that it helps manufacturers identify weak spots in their packaging. Whether it’s an insufficient amount of cushioning, weak seals, or structural vulnerabilities, drop testing uncovers these issues, enabling businesses to reinforce their designs before mass production begins.

2. Cost Savings on Returns and Damaged Goods

Shipping damage can lead to expensive returns, replacements, and repairs. By using a Drop Tester, manufacturers can ensure that their packaging will withstand the impacts it might encounter, reducing the chances of damage during transit. This results in lower costs related to damaged goods, as well as fewer returns and replacements, ultimately saving businesses money.

3. Enhanced Customer Satisfaction

When customers receive their products in perfect condition, their experience with your brand improves significantly. A Drop Testing helps ensure that products are well-protected during shipping, which leads to higher customer satisfaction, fewer complaints, and better overall reviews. Customers will be more likely to return for future purchases if they are confident that their orders will arrive safely.

4. Compliance with Packaging Standards

Various industries have strict packaging standards, especially for items like electronics, pharmaceuticals, and food products. A Drop Tester ensures that your packaging meets these regulations, preventing any potential legal issues and ensuring that products are shipped safely and securely. Complying with industry standards also boosts your brand’s credibility and reliability.

Why Choose Pacorr’s Drop Tester?

Pacorr's Drop Tester is designed to provide manufacturers with a reliable and accurate testing method to evaluate packaging durability. It offers flexibility, allowing for adjustments in drop height and surface type to simulate different shipping conditions. This customization ensures that the packaging is tested under real-world scenarios, giving businesses the data they need to make informed decisions.

With Pacorr’s Drop Tester, manufacturers can:

Assess packaging under varying conditions, such as height and surface impact

Identify weaknesses early in the design process, allowing for quick adjustments

Save on shipping costs and avoid damage-related expenses

Improve customer satisfaction by ensuring products are well-protected

Conclusion

Testing your packaging with Pacorr's Drop Tester Price is a crucial step in ensuring that your products arrive safely at their destination. By simulating real-world shipping impacts, you can assess the strength and durability of your packaging, reducing the risk of damage and protecting your bottom line. Investing in Pacorr’s Drop Tester helps you optimize your packaging, enhance customer experience, and comply with industry standards.

To learn more about Pacorr’s Drop Tester, visit pacorr.com.